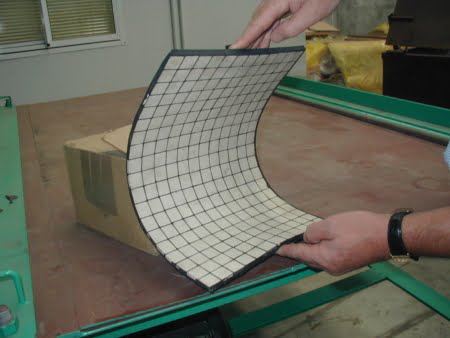

Oreflow are proud to announce rubber backed ceramic tiles to further expand our range of wear resistant materials. Our range of rubber backed ceramic tiles includes the CR 500-10/4, which is suitable for lining chutework where other linings are less effective. The mixture of rubber and ceramic gives a long life with the ability to absorb shock loads and excellent sliding abrasion. The CR 516 comes in 10mm, 6mm and 4mm thick tiles and is easy and cost effective to install on new equipment or as on site retro fit.

- P/N CR 500-13/4

- P/N CR 500-10/4

- P/N CR 500-6/4

- P/N CR 500-4/4

Nominal Sheet Size: | 500 x 500 |

Rubber Thickness: | 4mm |

Rubber Type: | VULCANISED NATURAL RUBBER COMPOUND |

Shore Hardness: | 45 (+-5) |

Rubber Tensile Strength: | 2710psi |

Rubber Elongation: | 600% |

Rubber/Ceramic Bond: | CHEMLOK PRE TREATMENT PRIOR TO HOT PRESSURE VULCANISING |

Ceramic Tile Thickness: | 10mm/6mm/4mm |

Ceramic Tile Size: | 20mm sq 576 PER SHEET |

Alumina Specification: | 90% ALUMINA BALANCE SILICA+BINDERS FLEXURAL STRENGTH @ 20 C (MOR) 338 MPA COMPRESSIVE STRENGTH @ 20 C 2482 MPA TENSILE STRENGTH @ 25 C 221 DENSITY (TYPICAL) +3.55 g/cc |

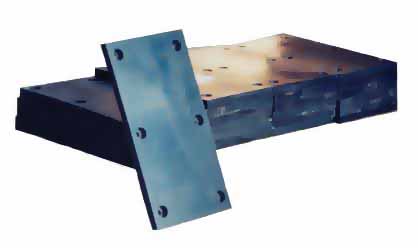

The CR 500-10/4 is easily installed by means of bonding directly to the steelwork. The Steelwork must be clean and free from loose material and rust. The steel is then primed with Oreflow T Metal Primer or equivalent. Once this is dry buff the back of the panel, panel can then be bonded to the steel using Oreflow Specbond 32 glue or equivalent.

The CR 500-10/4 is easily installed by means of bonding directly to the steelwork. The Steelwork must be clean and free from loose material and rust. The steel is then primed with Oreflow T Metal Primer or equivalent. Once this is dry buff the back of the panel, panel can then be bonded to the steel using Oreflow Specbond 32 glue or equivalent.