AirSweep® – Material Activation System

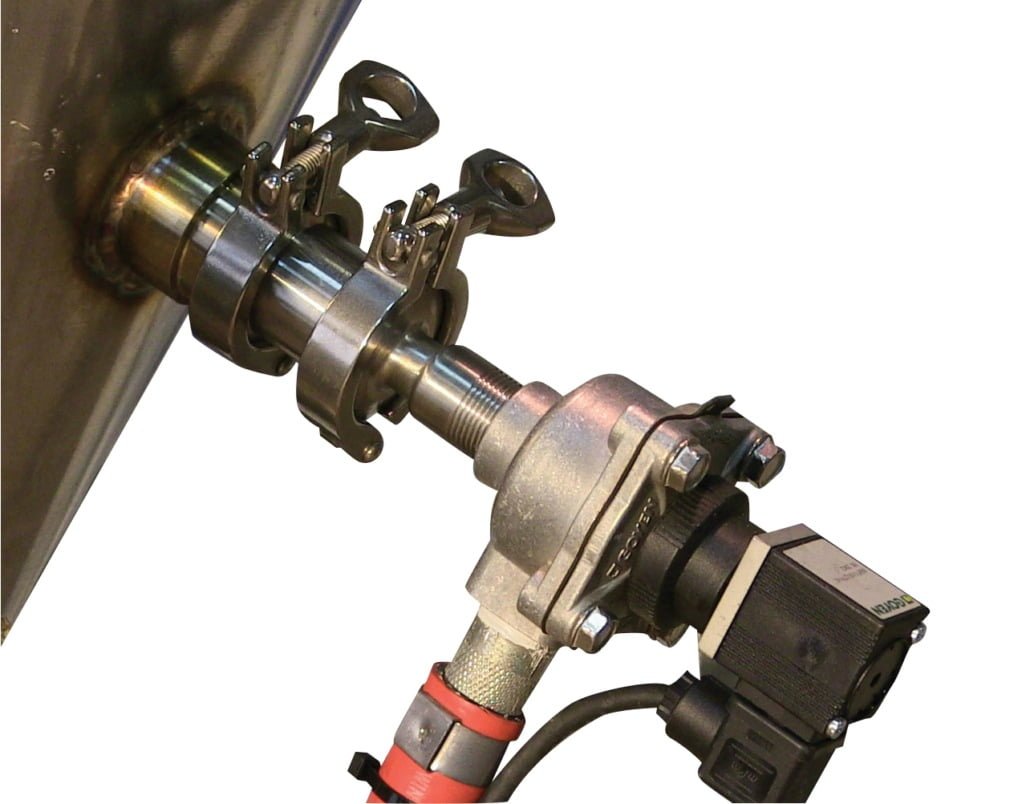

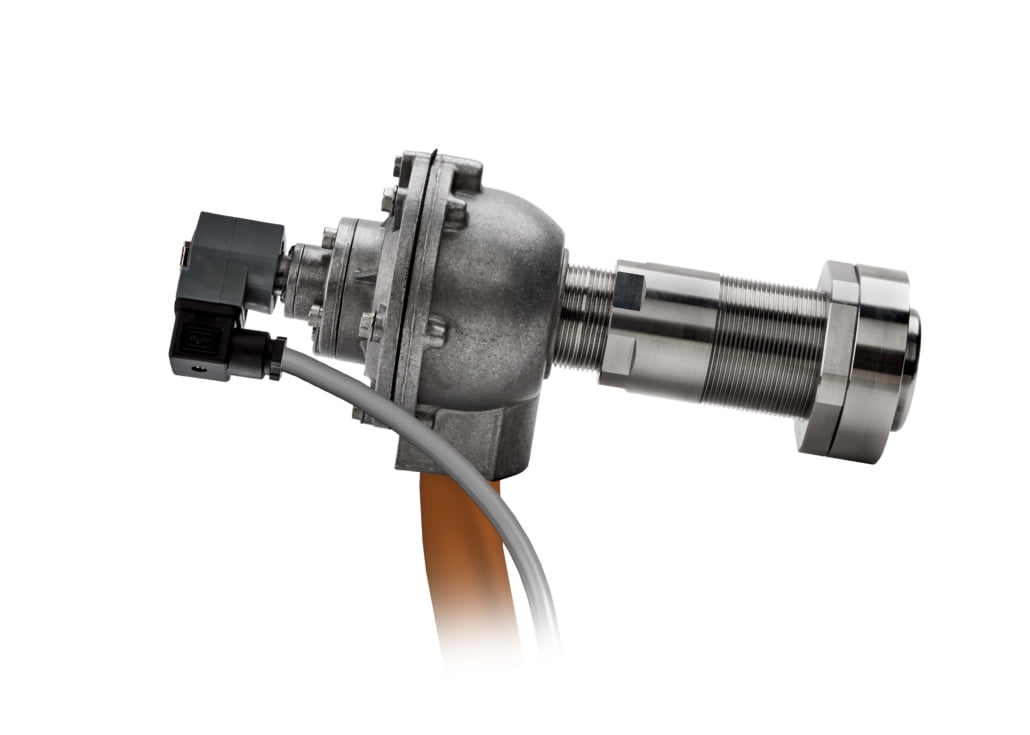

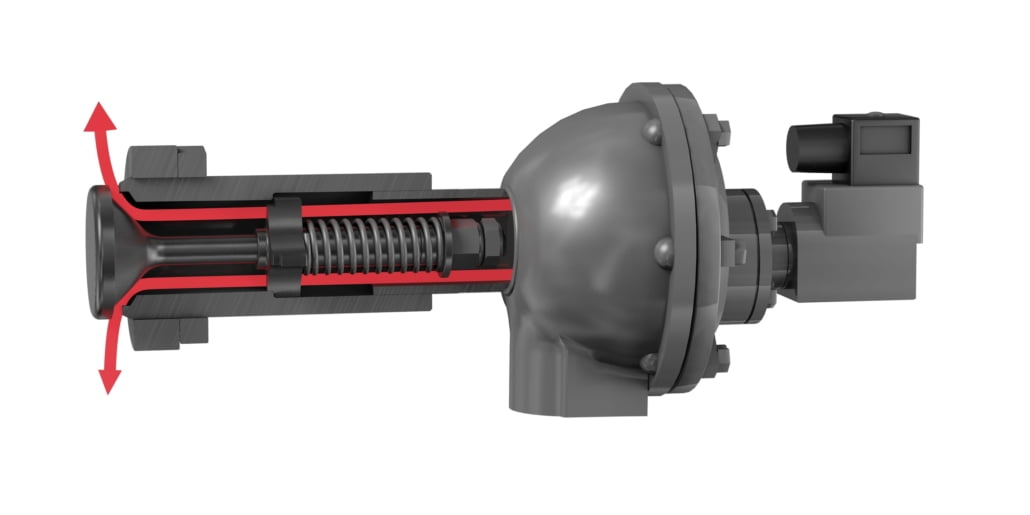

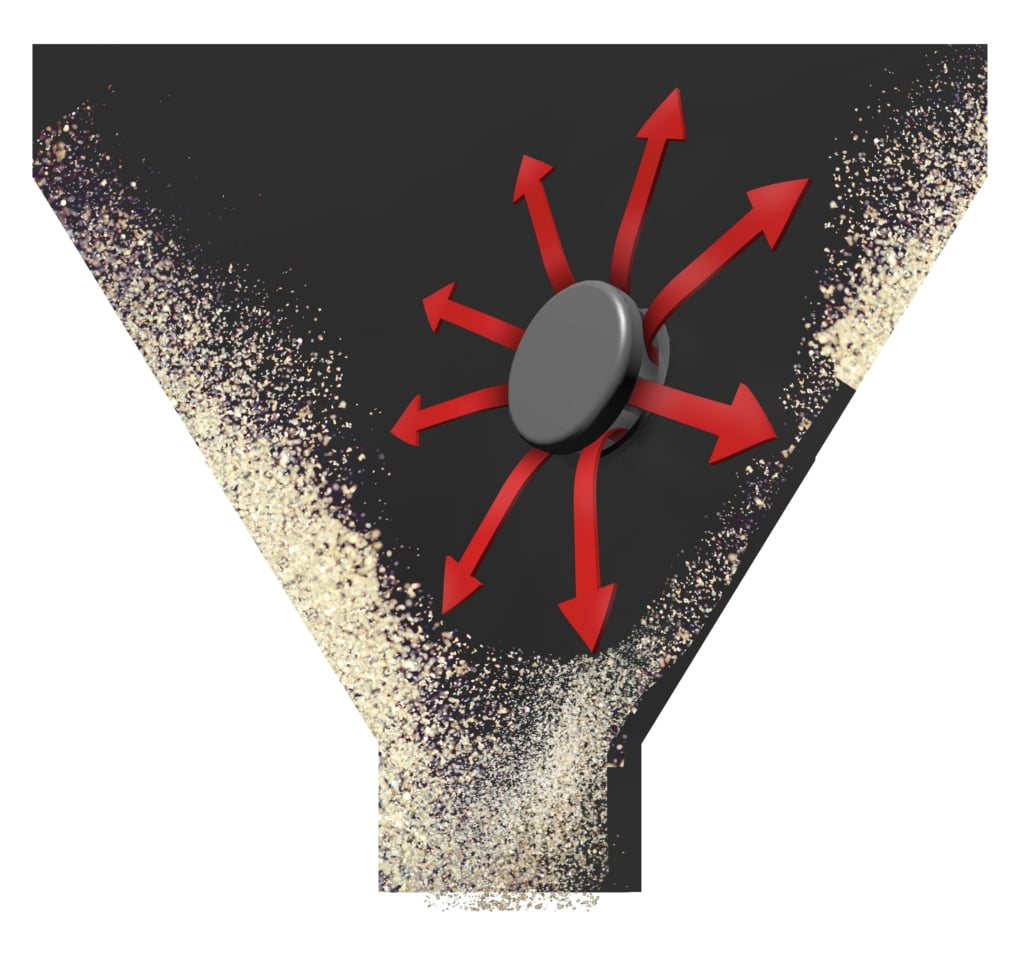

AirSweep material activation systems, available at Oreflow, are the ultimate solution to prevent and solve material hang-ups and blockages in bins, hoppers, chutes, and silos. These systems utilize powerful 360-degree bursts of compressed air or gas, effectively activating materials up to a 20cm diameter without causing vibration or stress. Designed for ease of use, AirSweep systems are installed and maintained externally, allowing for hassle-free operation. They are also versatile, easily retrofittable to any application, and can withstand temperatures up to 482°C.

The innovative design of AirSweep, featuring a patented valve with just one moving part, guarantees an immediate reseal after each pulse. This prevents material feedback and ensures a low-maintenance, efficient performance, making it an ideal choice for various industrial applications. Choose AirSweep for a reliable, maintenance-free solution to maintain consistent material flow in your operations.

Key Features

Competitive Analysis: AirSweep Versus Traditional Flow-Aids

Dive into an in-depth competitive analysis of AirSweep™ against other flow-aid solutions in the market. Our detailed comparison documents, available for download as PDFs, offer a thorough examination of how AirSweep™ stands out in efficiency, design, maintenance, and overall performance. Understand the key differences and advantages of choosing AirSweep™ for your material handling needs, backed by data and real-world applications. Click on the buttons below to access each analysis and make an informed decision about the best flow-aid solution for your operations.