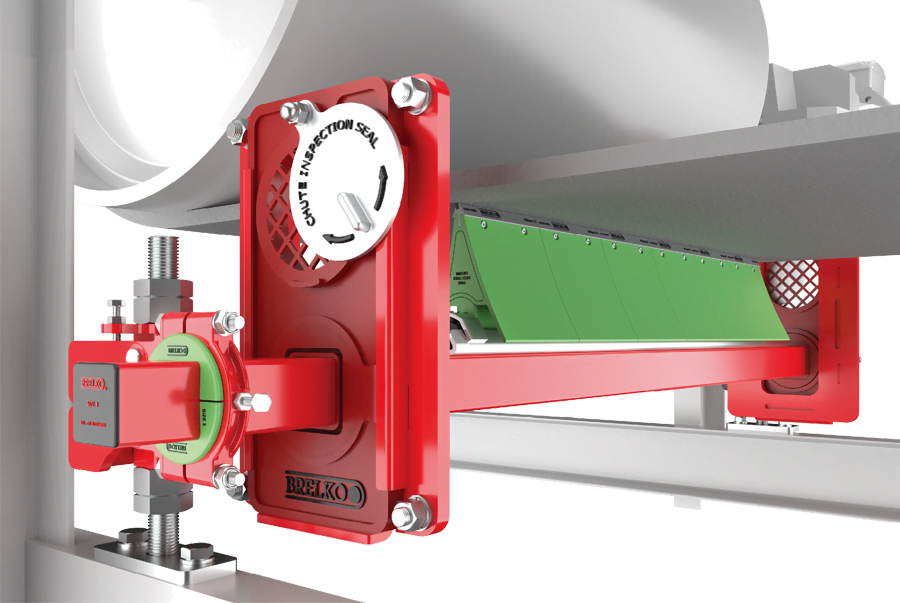

E255 Premium Secondary Heavy Duty Belt Cleaner

Applications

- Universal choice for heavy duty cleaning applications. Specially suited for wider high speed belts.

- Not suitable for mounting directly onto the head pulley.

- Use in conjunction with torsion arms to accommodate different belt thicknesses on the same conveyor and

excessive belt movement due to pulley eccentricity, thereby ensuring constant pressure with the belt. - Selection of correct blade material gives optimum blade life under all operating conditions and conveyed materials.

Features

- Patented V-base torsion holder makes blade changing quick and simple.

- Fully sealed construction of torsion holder prevents material build-up or ingress into the spring unit.

- Twin arm design of the torsion holder prevents radial and lateral blade oscillations and only allows longitudinal blade

movement thus ensuring uniform and constant blade contact with the belt, irrespective of variations in belt thicknesses

and surface conditions. - Pre-tensioned blades restrict forward movement and reduces belt contact pressure for optimized cleaning, and extends

belt life. - Lightweight polymeric material used for the torsion holder ensures ease of handling, corrosion protection and minimum

impact on belt surface aft er deflection. - Patented blade torsion holder and blade design incorporating a deflector skirt ensures accurate assembly and a clean

running scraper. - Brelko self adjusting torsion mountings allow the scraper to maintain a constant pressure on the belt and greatly

extends adjustment intervals, also available is the standard adjustable mounting. - All metal components can be made from corrosion resistant materials.

- Robust construction for longer life.

Spares